MIT researchers have developed one filiform rechargeable lithium-ion battery which can be folded, rolled, and even integrated into fabrics. Such a battery, of course, could enable the realization of a wide variety of wearable electronic devices as well as being used to make 3D printed batteries of any shape which could also act as structural parts of some types of devices.

Up to now, different types of fibers have already been made capable of containing a wide variety of electronic components including LEDs and photosensors. However, these fibers always needed to be fed from an external source. The battery made by MIT could now allow these devices to be completely autonomous.

All the work, supported by the MIT MRSEC program of the National Science Foundation, from US Army Research Laboratory through the Institute for Soldier Nanotechnologies, from the National Science Foundation, and National Research Foundation of Korea, was featured in the magazine Materials Today.

To demonstrate the possibilities offered by this type of technology, the researchers made a flexible fiber battery about 140 meters long and with a 123mAh energy storage capacity, therefore able to recharge even smartwatches. The fiber device is only a few hundred microns thick and is the thinnest ever produced. The construction of a 140-meter-long fiber battery, according to the researchers, proves that

there is no obvious upper limit to the length. We could certainly achieve a length on a kilometer scale.

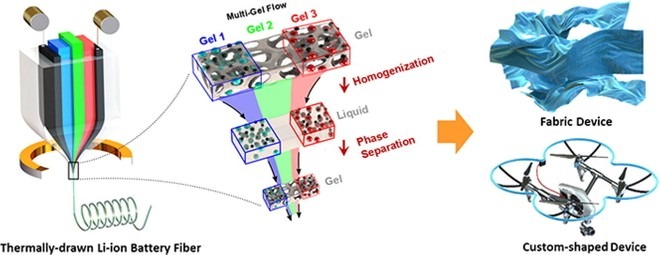

The battery was produced using new gels for electrodes and electrolytes and through a cylindrical extraction system that contains all the components that are heated and released through a narrower opening that reduces the diameter while maintaining all the original arrangement of the parts.

The fiber battery continues to power an LED even after a partial cut indicating that the fiber battery system is free from electrolyte leaks and shorts.

Even if cut, the fiber battery does not lose electrolytes and is free from short circuits. Unlike other types of similar batteries, this one developed by MIT integrates lithium and other materials inside, with a protective outer coating that also makes it more stable and waterproof.

For the demonstration, the fiber battery was used to transmit data via pulses of light in a “Li-Fi” communication system consisting of a microphone, a preamplifier, a transistor, and diodes capable of establishing an optical data link between two. devices.

According to MIT’s Jung Tae Lee,

The great thing about our technology is that we can incorporate multiple devices into a single fiber unlike similar products which require more fiber.

To date, it has been shown that it is possible to integrate LED and lithium-ion batteries into a single fiber, but in the future, it will be possible to combine even more than three or four devices in such a small space.

As mentioned, in addition to the single fibers, which can be woven to produce two-dimensional fabrics, the material can also be 3D printed to create customized shapes, such as casings that could provide both the structure of a device and its power source. To demonstrate this, the researchers wrapped a small toy submarine with a fiber battery that supplies it with power.

The research team has already applied for a patent for the entire construction process and will continue to make improvements to increase power and efficiency. These fiber batteries, according to the researchers, may be ready to be used in commercial products within a few years.